ALBA Synchrotron

A research led by ITQ (UPV-CSIC) has demonstrated the possibility to replace molecular catalysts in solution for all-solid catalysts based on isolated metal atoms for selective gas-phase ethylene hydroformylation, an important industrial chemical reaction.

The discovery paves the way for greener chemical processes, with greater energy efficiency and lower carbon footprint, for the valorization of unconventional raw materials, alternative to crude oil. To test the designed catalyst, synchrotron light techniques have been used, among others, at the ALBA Synchrotron.

The hydroformylation of ethylene is a chemical process of remarkable industrial significance. In particular, this chemical reaction entails the net addition of a formyl group (-CHO carbon, hydrogen and oxygen) and a hydrogen atom to the ethylene carbon-carbon double bond. This process enables valorizing raw materials such as refinery off-gases as well as unconventional feedstocks such as shale-gas (a kind of natural gas) into oxygenated platform chemicals. Moreover, hydroformylation is also considered a reactive separation alternative to current cryogenic distillations, which are applied to recover ethylene, a valuable commodity chemical, from mixtures with less valuable gases such as ethane. Such cryogenic distillation separations count among the most energy demanding operations in the chemical industry and are therefore associated to high carbon footprints.

Catalysts are materials that are central to steering essentially all chemical transformations of the current chemical industry. A major class of industrially applied catalysts consists of molecular organometallic compounds that operate in a liquid solvent. These catalysts have proven to be highly active and exceedingly selective for a wide range of important transformations. However, they also face significant challenges. First, their limited thermal and chemical stability, which shortens their functional lifetime. On the other hand, the technical complexity associated with their recovery from liquid mixtures with products and solvents of the process, to prevent losses of the precious metals these catalysts are typically made of.

Now, scientists from the Instituto de Tecnología Química (ITQ, UPV-CSIC), the , the Institute for Nanoscience & Materials of Aragón (INMA, CSIC-UZ) and the Karlsruhe Institute for Technology have designed a new catalyst for selective gas-phase ethylene hydroformylation. Their research shows that a material bearing isolated atoms of rhodium (Rh) stabilized within the surface of stannic oxide (SnO2) is an all-inorganic solid catalyst which delivers an exceptional performance for the gas-phase hydroformylation of ethylene, in par with those thus far exclusive for conventional molecular catalysts in liquid media.

In other words, the study demonstrates the possibility to replace molecular catalysts in solution for all-solid catalysts based on isolated metal atoms. The discovery paves the way towards greener chemical processes, with greater energy efficiency and lower carbon footprint, for the valorization of unconventional raw materials, alternative to crude oil.

"Separating gas molecules with very low and very similar boiling points entails enormous amounts of energy. Ethylene hydroformylation can selectively convert the ethylene present in complex mixtures to propanal, a molecule with over 150 ºC higher boiling point, which is therefore very easy to separate from the mixture of less valuable compounds at temperatures close to ambient. This would massively reduce the energetic costs of such separations and contribute to the transition to a greener chemical industry. While the reaction has long been implemented with molecular catalysts in liquid media, our study now unlocks this transformation on solid catalysts, which are more stable, and easier to isolate and handle than their molecular counterparts, and hence strongly preferred for industrial deployment", explains Gonzalo Prieto, CSIC scientist at ITQ and leading researcher of the study.

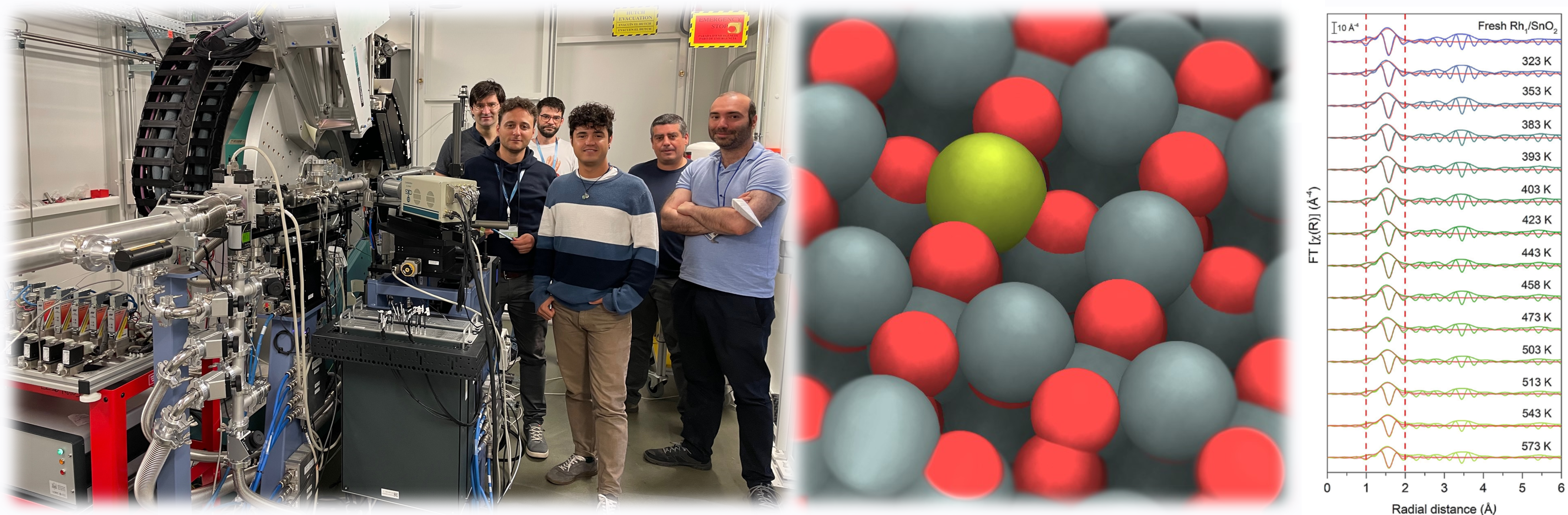

This research has used different techniques. On the one hand, laboratory techniques like X-ray diffraction (XRD), Raman spectroscopy and scanning-transmission electron microscopy. On the other hand, synchrotron techniques like X-ray absorption spectroscopy (XAS) measured at the Rh K-edge in both and beamlines of ALBA. The combination of all of them have made possible to follow the structural and electronic evolution of the single-atom catalysts, showing how Rh atoms remain isolated, within the tin oxide surface, during their catalytic "action". Part of the experiments were performed at newly installed flow XAS/XRD set-ups, developed by the ITQ researchers in collaboration with ALBA scientists (Carlo Marini and Giovanni Agostini) as part of the RTI2018-096399-A-I00 project funded by the Spanish Ministry of Innovation, and the Interdisciplinary Thematic Platform Transición Energética Sostenible (PTI-TRANSENER+) as part of the CSIC program for the Spanish Recovery, Transformation and Resilience Plan. The systems enable quasi-simultaneous X-ray absorption and diffraction experiments on catalysts and other functional materials under operations conditions (gas-solid hydrodynamics, temperature, pressure, etc.) which closely mimic those which are relevant for the materials’ industrial deployment.