ALBA Synchrotron

Researchers from the CRSPD of the Polytechnic Institute of Leiria (Portugal) have been performing time-resolved in situ SAXS experiments at NCD beamline in ALBA to map the morphology of a scaffold and test its level of deformation in working conditions. The results of this research are expected to have a huge impact in improving the recovery process of bone injuries and fractures.

Tissue engineering is aiming at generating biological substitutes that are capable of restoring diverse tissue functions and this specific field is becoming of great importance in today's society. The growing elderly population and the search for less invasive treatments make tissue engineering one of the most promising techniques for human wellbeing. However, biomaterials are still very complex to obtain and further research needs to be done to develop the field of regenerative medicine.

A group of researchers, led by Geoffrey Mitchell, from the Centre for Rapid and Sustainable Product Development of the Polytechnic Institute of Leiria (Portugal) have designed and produced a biodegradable 3D structure that once implanted in the injured bone, helps to repair the tissue. This work is supported by the Portuguese Foundation for Science and Technology through the Strategic Project PEST-OE/EME/UI4044/2011.

This 3D structure acts as a scaffold that provides the appropriate environment for cells to develop and in time it is gradually being absorbed by the new growing tissue. This scaffold is made of a polymer which is as porous and as hard as bone, and it tries to mimic as much as possible human tissue.

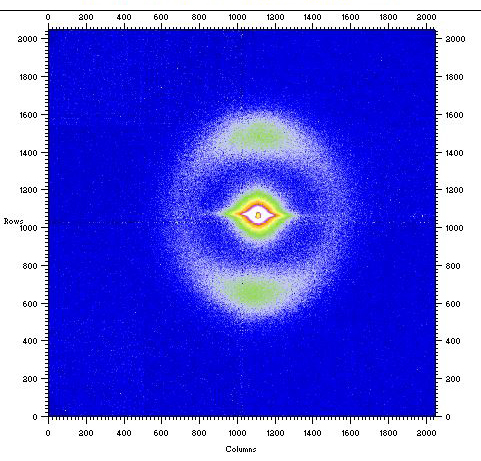

Researchers have used synchrotron light at NCD (Non-Crystalline Diffraction) beamline in ALBA, in order to examine the morphology of the polymer used in the scaffold. "The success of this material relies on the structure of the scaffold. This is why it is so important to know in detail the chemical composition and physical architecture of the 3D matrix we have created", says Geoffrey Mitchell, main researcher of the experiment. While collecting x-ray data, the research group have also tested the mechanical resistance of the scaffold, using a tensiometer, in order to evaluate structural changes in polymer morphology while applying mechanical deformation in situ.

ALBA and CDRSP researchers inside the experimental hutch of NCD beamline. CDRSP researchers preparing the sample before diffraction experiment.

The results of this research will be extremely beneficial in improving the treatment of bone injuries and fractures, as they will aim at developing new methods of surgical intervention that will avoid consecutive follow up operations, and they will also promote the development of new research areas in tissue regeneration.

This material has been successfully tested in sheep due to a collaboration with the University of Queensland (Australia). The following step will be trying this material in other animals with the aim of having this technique available for humans in the next five years.

The Centre for Rapid and Sustainable Product Development (CDRSP) is a research centre hosted by the Polytechnic Institute of Leiria (IPL, Marinha Grande, Portugal) and focuses its research on emerging technologies, advanced materials and sustainable manufacturing.

Figure 1. A time-resolved small-angle x-ray scattering pattern recorded for a scaffold strand prepared using the bioextruder at CDRSP using a biodegradable polymer poly(caprolactone) at the start of the mechanical extension. The pattern reveals the high level of preferred orientation of the polymer crystals in the strand. This has a significant impact on the mechanical properties of the scaffold and the subsequent rate of absorption after implantation.